Jerry cans are essential for safely transporting liquids like water, medical fluids, and chemicals across industries and relief efforts. In high-stakes sectors, only containers meeting strict global standards—like those from the UN and WHO—are suitable.

Understanding Jerry Cans and Their Global Applications

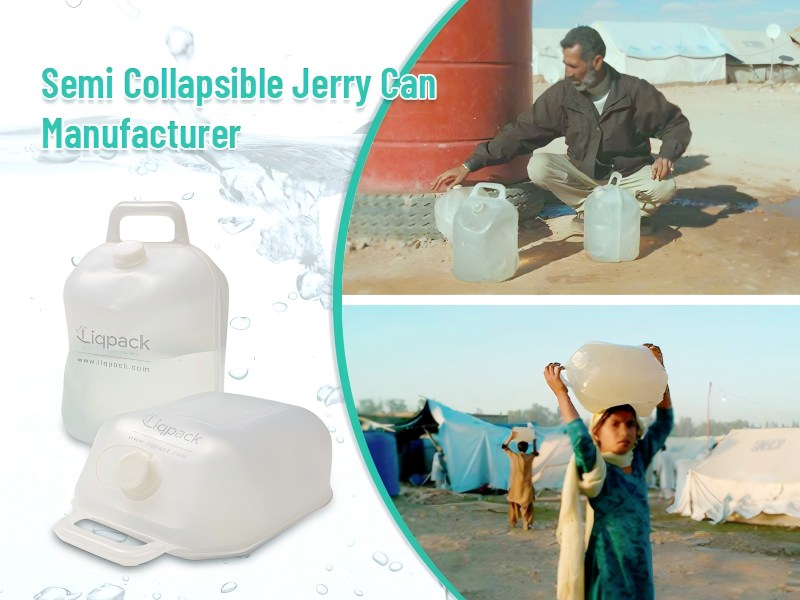

Jerry cans, originally developed for military use, are now widely used in sectors such as healthcare, disaster relief, food aid, agriculture, and industry. They come in several types: rigid, fully collapsible, and semi-collapsible jerry cans. Among these, semi-collapsible jerry cans have gained popularity for their balance of structure and flexibility.

Their global applications include:

- Emergency water supply in disaster zones

- Transportation of chemicals and fuels

- Safe storage of drinking water in remote areas

- Humanitarian supply chains in conflict zones

These cans are especially crucial in regions with limited infrastructure, where portability, durability, and space efficiency are essential.

Overview of UN and WHO Standards

To ensure safety and reliability, jerry cans must meet specific UN and WHO standards, especially when used in global humanitarian and medical contexts.

Important UN Standards:

- The UN Committee of Experts on the Transportation of Dangerous Goods issued this document.

- Focus on hazardous materials packaging

- Require Jerry cans to pass tests such as drop resistance, pressure resistance, and stack load endurance

- Outlined in the WHO Technical Notes for Emergencies and Water and Sanitation Guidelines

- Focus on hygiene, safety, and user-friendliness

- Require the use of non-toxic, food-grade materials and cleanable surfaces

- Emphasize volume accuracy, labeling, and secure closures

By following these benchmarks, Jerry cans help ensure that aid materials and sensitive contents arrive safely and uncontaminated.

Structural Requirements for Compliance

UN and WHO-certified jerry cans undergo rigorous testing and must meet detailed structural specifications:

- Material Strength: Containers must be made from high-density polyethylene (LDPE) or similar durable plastics that resist cracking, impact, and chemical corrosion.

- Drop Resistance: UN testing standards include dropping the filled jerry can from 1.2 meters to ensure it does not rupture or leak.

- Stack Load Endurance: Cans must hold up under the weight of stacking during transit, especially in cargo shipments.

- Closures: Caps and spouts must be leak-proof, easy to open/close, and compatible with the stored liquid.

Semi-collapsible models strike an excellent balance between flexibility and robustness. Their partially rigid structure provides form stability while reducing empty space during transport or storage.

Hygiene and Sanitation Compliance (WHO Focus)

In medical and humanitarian settings, sanitation is non-negotiable. WHO standards mandate that water containers:

- Be made from food-safe, non-toxic materials

- Be free from sharp edges or crevices where bacteria can accumulate

- Make cleaning and disinfection simple.

- Guard against microbiological growth and UV deterioration.

Semi-collapsible jerry cans are typically manufactured using virgin LDPE or other certified plastics. Their smooth, sealable design ensures water or other contents remain safe for consumption, even in hot, humid, or unsanitary environments. The ability to collapse them slightly also facilitates full drainage and cleaning.

Labeling and Traceability Standards

Correct labeling is critical for safety, especially when transporting chemicals or pharmaceuticals.

UN requirements include:

- UN number indicating the type of dangerous good

- Manufacturer’s code and batch identification

- Volume capacity and material type

WHO guidelines also encourage:

- Color-coding (e.g., blue for potable water, red for fuel)

- Labeling for hygiene use (e.g., “Drinking Water Only”)

- Instructions for use, especially in multilingual relief settings

Semi-collapsible cans can easily be printed with these labels during manufacturing or fitted with tamper-evident seals and tags.

Environmental and Reusability Standards

Both the UN and WHO promote sustainability and reduced environmental impact in their procurement policies. Jerry cans must be:

- Reusable: Withstand multiple uses without deforming or losing integrity

- Made from materials that can be processed using standard recycling methods, recyclable

- Lightweight: To reduce the carbon footprint during transport

- Space-efficient: Collapse or nest to save on logistics costs

Semi-collapsible models are specifically designed to align with these principles. Their foldable structure helps minimize the storage footprint while still providing strength and integrity when filled.

Semi-Collapsible Jerry Cans: Key Features

Unlike rigid or fully collapsible cans, semi-collapsible jerry cans offer a hybrid design optimized for both form and function:

- Shape Retention: Rigid frame ensures stability when filled

- Collapsibility: Folds partially flat for easy transport when empty

- Carrying Ease: Equipped with strong handles, often dual-grip

- Spout Compatibility: Built-in nozzles or spigots for controlled pouring

- Durability: Withstands impact, stacking, and repeated use

These features make semi-collapsible jerry cans ideal for field deployment, refugee camps, mobile clinics, and rapid-response units.

How Semi-Collapsible Models Meet UN Standards

To be UN-certified, semi-collapsible jerry cans undergo a series of performance tests:

- Leakproof Test: Ensures the cap and body seal correctly under pressure

- Drop Test: Simulates a container falling during handling or shipping

- Vibration Test: Imitates conditions during transport

- Stacking Test: Checks whether the container withstands vertical pressure

Approved models are given a UN code marking, confirming compliance. These models are often used to transport:

- Pesticides and fertilizers

- Flammable liquids and fuels

- Industrial and medical chemicals

Their versatility across sectors and compatibility with UN transport guidelines make them the go-to choice for many global supply chains.

How They Meet WHO Specifications

Semi-collapsible jerry cans are also widely accepted in public health and emergency water supply programs governed by the WHO.

They meet key requirements such as:

- Safe material composition for clean drinking water

- Strong, sealable closures to prevent contamination

- Clear measurement marks for dosage and monitoring

- Lightweight construction for ease of use by women, children, and elderly individuals

- Ergonomic design for pouring and carrying

WHO’s logistics operations, often in collaboration with UNICEF, favor these models in rural immunization drives, cholera prevention efforts, and emergency hydration distribution.

With rising global regulations, compliant packaging is essential. Semi-collapsible jerry cans combine innovation, durability, and safety—meeting UN and WHO standards. Trusted in relief, industry, and medical use, they help organizations operate efficiently while meeting global best practices and protecting lives and the environment.

- Liqpack