Containers are essential tools in laboratories and industrial facilities. They are used to store, transport, mix, or process a wide variety of materials—from chemicals and solvents in research labs to bulk raw materials in manufacturing plants.

This article will explore practical tips for using containers in laboratory and industrial settings, covering container types, material selection, labeling, cleaning, safety regulations, storage strategies, and long-term maintenance. By adopting these practices, professionals can extend the life of their containers, reduce costs, and improve workplace safety.

Choose the Right Container Material

Laboratory Settings

In laboratories, materials must match chemical compatibility. Common options include:

- Glass containers – Ideal for solvents and corrosive reagents, resistant to heat, but prone to breakage.

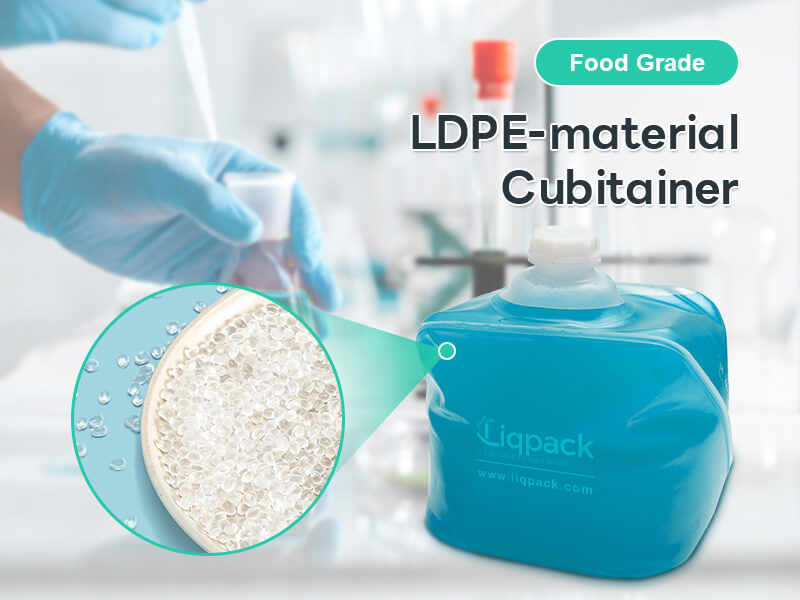

- Plastic containers (HDPE, PP, PTFE) – Lightweight, shatter-resistant, suitable for acids and bases, but some plastics leach or absorb chemicals.

- Metal containers (stainless steel, aluminum) – Durable, used for storing powders or inert gases, but can react with strong acids.

Industrial Settings

Industrial use often requires larger containers with structural strength:

- Steel drums – Rugged, ideal for oils, fuels, and hazardous materials.

- Intermediate Bulk Containers (IBCs) – Common for transporting bulk liquids, available in plastic or composite builds.

- Fiber drums – Cost-effective for dry goods like powders or granules.

Tip: Always consult chemical compatibility charts when choosing container material. Even small mismatches can lead to degradation, contamination, or accidents.

Make accurate labeling and identification a top priority.

One of the most frequent reasons for industrial and laboratory mishaps is incorrect or absent labeling. Labels should include:

- Chemical name and concentration

- Hazard classification (flammable, corrosive, toxic, etc.)

- Date of filling or preparation

- Responsible person or department

In industrial settings, large containers should also have barcodes or RFID tags to integrate with inventory systems, enabling real-time tracking.

Tip: Use solvent-resistant and weatherproof labels to ensure durability. Labels shouldn’t peel or fade in areas that are often cleaned or exposed to the elements.

Implement Cleaning and Decontamination Protocols

Reusing containers saves costs but only if cleaning is thorough.

- Laboratories: Adopt standardized cleaning methods—acid washes, solvent rinses, or autoclaving depending on chemical residue.

- Industries: Invest in container washers for drums and IBCs to maintain hygiene and reduce downtime.

Best Practices:

- Never mix incompatible cleaning agents.

- Ensure containers are dried completely before reuse to prevent unwanted reactions.

- For hazardous materials, follow disposal regulations for rinse water and waste.

Use Secondary Containment for Hazardous Materials

Spills and leaks are inevitable, especially in industrial transport. Secondary containment acts as a safeguard:

- Laboratory: Trays or spill-proof cabinets beneath reagent bottles.

- Industrial: Spill pallets, bund walls, or containment berms for drums and IBCs.

Tip: Regulations such as OSHA and EPA (in the U.S.) often mandate secondary containment for hazardous chemicals. Always ensure spill capacity exceeds 110% of the largest container volume.

Control Environmental Conditions

Both laboratory and industrial containers are sensitive to external conditions.

- Temperature: Use insulated containers for items that are sensitive to temperature changes and keep volatile solvents in cool places.

- Humidity: Prevent rusting of metal containers and degradation of hygroscopic materials (e.g., salts).

- Exposure to light: Keep photosensitive substances (such as silver salts) in opaque containers or amber glass.

Tip: Dedicated climate-controlled storage reduces chemical degradation and prevents industrial material losses.

Adopt Safe Handling Practices

Container handling directly affects worker safety.

- Use appropriate PPE (gloves, goggles, lab coats, or industrial overalls).

- Never overfill containers; leave headspace for expansion.

- Lift properly; in industrial settings, use forklifts or drum lifters instead of manual handling.

Tip: Train workers regularly on container handling, especially new hires, to reduce accidents.

Ensure Proper Sealing and Closures

Improper sealing can lead to spills, contamination, or product loss.

- Lab containers: Use PTFE-lined caps for volatile solvents.

- Industrial containers: Check gaskets, bungs, and valves for wear before filling.

- Transport: Verify UN/DOT-approved closures for hazardous materials.

Tip: Implement a routine inspection schedule to replace worn-out seals before leaks occur.

Optimize Container Storage Layout

Laboratory Storage

- Store chemicals alphabetically by class, not name.

- Segregate acids, bases, oxidizers, and flammables.

- Use explosion-proof cabinets for volatile solvents.

Industrial Storage

- Stack drums no more than three high to prevent collapse.

- Use pallet racking systems for space efficiency.

- Keep aisles clear for forklift movement.

Tip: Create digital storage maps linked with inventory systems to prevent misplacement and reduce retrieval time.

Integrate Containers into Waste Management Systems

Containers also play a role in waste collection.

- Lab waste: Collect organic and inorganic wastes separately in compatible containers.

- Industrial waste: Use color-coded drums for easy identification of hazardous vs non-hazardous waste.

Tip: Clearly mark waste containers with “Waste Only” to avoid accidental reuse.

Compliance with Regulations and Certifications

Safety and transportation regulations must be followed by both industries and labs. Common standards include:

- UN/DOT markings for transport of hazardous goods.

- ISO standards for container manufacturing and testing.

- Local EPA or environmental authority guidelines for waste disposal.

Tip: Choose certified containers from reputable suppliers to ensure compliance and avoid legal risks.

Train Staff Regularly

Human error is a major risk factor. Training should cover:

- Chemical compatibility basics

- Correct labeling procedures

- Emergency response for spills and leaks

- Container maintenance and inspection routines

Tip: Conduct refresher courses annually and update training when new materials or containers are introduced.

Monitor Container Lifespan and Replace Proactively

Containers wear out over time due to corrosion, UV exposure, or physical stress.

- Lab glassware: Replace chipped or cracked bottles immediately.

- Plastic containers: Watch for brittleness, discoloration, or swelling.

- Industrial drums: Inspect for dents, rust, or weakened seals.

Tip: Keep a logbook or digital record of container lifecycles to predict replacement needs before failures occur.

Use Containers to Improve Efficiency

Containers are not just passive storage; they enhance workflows:

- Batch preparation: Pre-measure reagents in smaller lab containers for efficiency.

- Bulk distribution: Use IBCs in factories to reduce refilling time compared to smaller drums.

- Automation compatibility: Select container types that integrate with filling lines or robotic handling systems.

Tip: Evaluate total cost of ownership (container cost, cleaning, downtime) instead of just purchase price.

Embrace Smart Containers and Tracking

- Technology integration is rising in both labs and industries.

- RFID-enabled containers: Provide real-time tracking of materials.

- IoT sensors: Monitor temperature, pressure, or liquid level inside containers.

- Smart caps: Indicate tampering or improper sealing.

Tip: While initial investment is higher, smart containers reduce losses, improve compliance, and enable predictive maintenance.

Sustainability in Container Use

Sustainability is increasingly important:

- Opt for reusable containers over single-use options.

- Establish return and reuse programs with suppliers.

- Choose materials with recycling pathways, such as HDPE or stainless steel.

- Reduce hazardous waste by improving segregation and reuse.

Tip: Highlight sustainable container practices in compliance reports and CSR initiatives.

Containers may appear to be simple vessels, but in laboratory and industrial contexts, their selection and use carry significant consequences. From preventing chemical accidents to improving workflow efficiency, the right container practices enhance safety, compliance, and sustainability.

By choosing the right materials, ensuring proper labeling, maintaining cleaning and handling protocols, adopting smart monitoring, and embracing sustainable practices, laboratories and industrial facilities can safeguard both people and processes. Proactive container management ultimately lowers costs, minimizes risks, and improves long-term performance.

- Liqpack