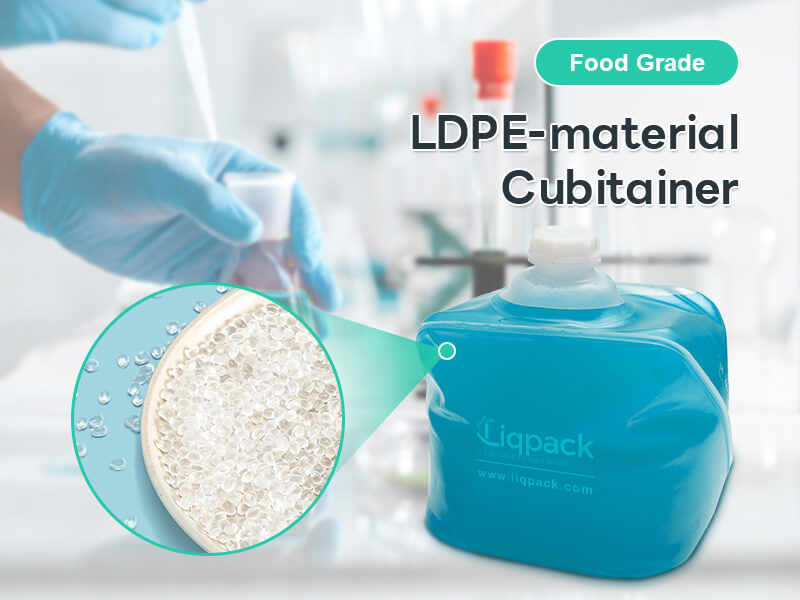

Cubitainers are lightweight, collapsible LDPE containers ideal for efficient liquid packaging across industries. This article explores how to optimize their filling process, minimize waste, and boost productivity.

What Is a Cubitainer?

A cubitainer (cube + container) is a semi-rigid, collapsible, blow-molded plastic container typically used to store and dispense liquids. Most models consist of:

- An inner flexible LDPE bag

- An external corrugated fiberboard box for structure

- A cap or valve system for filling and dispensing

Cubitainers come in standard volumes—usually 5L, 10L, 18L, and 20L—and are often used in Bag-in-Box systems or as standalone liquid packaging.

Why Optimize the Cubitainer Filling Process?

An unoptimized filling process may result in:

- Underfilling or overfilling, leading to product loss or customer complaints

- Excessive downtime from manual handling or inefficient equipment

- Contamination risks, especially for pharmaceutical or food-grade products

- High labor expenses as a result of manual tasks

- In high-volume production settings, low throughput

By optimizing the filling process, businesses benefit from:

- Better product consistency

- Lower costs per unit

- Higher throughput

- Improved hygiene and safety

- Reduced waste and downtime

Step-by-Step Breakdown of the Cubitainer Filling Process

Here is a simplified overview of the typical filling workflow and areas where optimization can be introduced:

Step 1: Pre-Fill Preparation

Tasks:

- Inspect the cubitainer and external box for integrity

- Verify cleanliness and sterility

- Assemble the inner bag and box (if separate)

- Align the cubitainer under the filling nozzle

Optimization Tips:

- Use automated bag insertion and unfolding machines to save time

- Implement pre-use inspection checklists for QA

- Store cubitainers in clean, climate-controlled areas to avoid contamination

Step 2: Filling the Liquid

Tasks:

- Use a volumetric, gravimetric, or timed filling machine

- Regulate the flow to avoid foaming and splashing.

- Monitor the fill level carefully

Optimization Tips:

- Choose the right filling technology:

Gravity fillers for water-like products

Piston fillers for viscous liquids

Peristaltic pumps for pharmaceuticals

- Use anti-foam nozzles or bottom-up filling for foamy liquid

- Calibrate filling volumes with sensors for consistent accuracy

Step 3: Capping and Sealing

Tasks:

- Attach the closure (screw cap, tamper-evident seal, valve, or spout)

- Tighten or seal properly to prevent leakage

Optimization Tips:

- Implement torque-controlled capping heads to ensure uniform seal tightness

- Use automatic cap feeders to reduce manual handling

- Employ inline cap detection systems for QA verification

Step 4: Outer Box Closing and Labeling

Tasks:

- Seal the external box

- Apply product and regulatory labels

- Date stamp or batch code each unit

Optimization Tips:

- Automate box folding and gluing/taping

- Integrate print-and-apply labeling machines for real-time tracking

- Include a barcode scanner for inventory and traceability

Step 5: Final Inspection and Packing

Tasks:

- Visual inspection for defects, leaks, or missing labels

- Load onto pallets for shipping or storage

Optimization Tips:

- Introduce automated vision inspection systems

- Use weigh-checkers to verify filled weight

- Employ robotic palletizers to reduce manual labor

Key Factors to Consider When Optimizing

Filling Speed vs. Accuracy

High-speed filling can compromise accuracy. Determine your tolerance for fill volume variation and choose equipment with proper precision.

-

- Use checkweighers to verify fill volume

- For high-value or sensitive products, prioritize accuracy over speed

Foaming and Splashing

Some liquids (e.g., soaps, detergents, wines) tend to foam. Splashing and foaming can cause underfills or contamination.

- Use bottom-up nozzles or slow-start valves

- Maintain optimal temperature to reduce foam formation

Liquid Viscosity

Different liquids require different pumping technologies:

| Liquid Type | Recommended Filling System |

| Low viscosity | Gravity or peristaltic pump |

| Medium viscosity | Piston filler or gear pump |

| High viscosity | Auger or servo piston systems |

Sterility and Hygiene

Food, medical, and pharma-grade cubitainers require aseptic filling:

- Use clean-in-place (CIP) systems

- Enclose filling areas in laminar airflow booths

- Install HEPA filtration in cleanrooms

Environmental Impact

Reducing waste and energy consumption adds long-term value:

- Choose energy-efficient filling machines

- Implement recyclable materials for boxes and closures

- Reduce spillage by pre-programming fill volume ranges

Manual vs. Semi-Automatic vs. Fully Automatic Filling

| System Type | Pros | Cons | Best For |

| Manual Filling | Low cost, flexible | Labor-intensive, inconsistent | Small batches, startups |

| Semi-Automatic | Balanced speed and control | Some manual handling still needed | Mid-sized operations |

| Fully Automatic | High throughput, consistent quality | High investment | Large-scale production |

Optimization Insight: Many manufacturers start with semi-automatic systems and scale up to full automation as demand grows..

Typical Errors and How to Prevent Them

Filling up too much

- Leads to leakage, mess, and packaging damage

- Use digital sensors and weigh checks

Underfilling

- Regulatory violation for retail products

- Calibrate your filling machine periodically

Loose or Misaligned Caps

- Causes leaks and product spoilage

- Integrate torque sensors and rejection systems

Inefficient Workflows

- Manual steps create bottlenecks

- Use layout planning to streamline station-to-station flow

Poor Label Placement

- Affects brand perception and compliance

- Use automatic label applicators with alignment guides

Maintenance and Quality Control

Routine maintenance is essential to sustain an optimized filling process. Key recommendations include:

- Daily: Clean nozzles and valves, inspect for leaks

- Check pump seals and calibrate fill volumes once a week.

- Every month, give moving parts preventive maintenance.

- Quarterly: Run full QA audits and traceability checks

Use Standard Operating Procedures (SOPs) and maintenance logs to ensure consistency and accountability.

Optimizing cubitainer filling is more than just using better machines—it’s about creating a seamless, hygienic, efficient, and scalable system from start to finish. Whether you’re working with small-batch medical liquids or high-volume industrial chemicals, adopting the right practices can dramatically improve your output and quality.

- Liqpack