Cubitainers offer a safe, efficient, and eco-friendly way to store and transport liquids across industries. Their collapsible design and liquid compatibility help reduce packaging waste and save space. With the right accessories, their performance improves even further, boosting dispensing accuracy, handling safety, and overall usability.

Why Accessories Matter in Cubitainer Use

While Cubitainer offers natural advantages like flexibility, stackability, and environmental friendliness, using them without appropriate accessories can limit their full potential. For example, dispensing liquids from a cubitainer without a tap can lead to spills and waste. Handling corrosive substances without secure closures or secondary containment could result in workplace hazards or environmental violations.

Accessories help address these challenges by:

- Enabling controlled dispensing and transfer

- Reducing the risk of leaks and cross-contamination

- Enhancing user safety in industrial and laboratory settings

- Supporting compliance with local and international regulations

Whether you’re using cubitainers in a laboratory, factory, agricultural setting, or commercial kitchen, selecting the right accessories ensures a seamless and secure liquid handling process.

Essential Accessories for Functionality

Dispensing Taps and Nozzles

Dispensing taps are among the most common and crucial accessories for cubitainers. They enable users to pour liquids with precision and control, minimizing spillage and exposure. There are several types of taps available:

- Standard taps for everyday use with water-based or non-corrosive liquids

- High-flow taps for fast dispensing in large volumes

- Precision nozzles for measured and exact flow in laboratory or pharmaceutical use

Many taps come with anti-drip designs or adjustable flow rates, making them suitable for sensitive operations like dosing chemicals or filling narrow-mouthed containers. For applications where cleanliness is key, taps with hygienic seals are recommended.

Caps and Closure Systems

Caps do more than just seal the cubitainer—they prevent contamination, evaporation, and tampering. Depending on your specific needs, there are various cap options:

- Tamper-evident caps to show if a cubitainer has been previously opened

- Vented caps that allow gases to escape while preventing leaks during transport

- Child-resistant caps for hazardous liquids like solvents or cleaners

Material compatibility is essential. For aggressive chemicals or solvents, use closures made from chemically resistant plastics like HDPE or polypropylene.

Adapter Fittings and Connectors

Adapter fittings help integrate cubitainers into your broader liquid handling system. These include:

- Threaded connectors that fit with hoses, pumps, or tubing

- Quick-connect couplers for fast liquid transfer

- Reducer fittings to connect different outlet sizes

With these accessories, cubitainers can easily connect to dispensing stations, bottling machines, or irrigation systems. This lowers labor costs and increases safety by eliminating the need for hand lifting and pouring.

Cubitainer Collars or Rigid Support Boxes

Because cubitainers are made from flexible plastic, pairing them with rigid outer boxes or collars helps maintain their shape during filling and use. These supports:

- Prevent bulging and tipping when full

- Allow safe stacking and transport

- Improve visual stability and shelf organization

Corrugated cardboard, HDPE frames, or reusable plastic crates are commonly used. In warehouse or distribution settings, these accessories reduce the chance of damage during handling.

Essential Accessories for Safety

Secondary Containment Trays or Spill Basins

No matter how durable the cubitainer is, accidents can happen. Secondary containment trays catch leaks or spills, helping facilities:

- Prevent liquid pooling on work surfaces or floors

- Stay compliant with OSHA and EPA regulations

- Minimize slip hazards and environmental contamination

These trays are especially important for cubitainers holding corrosive, flammable, or toxic liquids. High-capacity basins or bunded pallets are ideal for bulk storage.

Labels and Tagging Systems

Proper labeling is essential in every industry, especially when multiple cubitainers are used for different substances. Accessories like waterproof labels, barcode tags, or QR-coded stickers offer:

- Clear identification of contents and safety warnings

- Easy tracking for inventory or regulatory audits

- Instructions for proper usage, disposal, or emergency response

Custom labels can include chemical names, concentrations, hazard symbols, and expiry dates. Using durable, smudge-resistant labels ensures long-term visibility even in wet or industrial environments.

Protective Gloves and Handling Tools

Some liquids stored in cubitainers can pose health risks during pouring, refilling, or maintenance. Protective accessories like:

- Chemical-resistant gloves (nitrile, neoprene, or butyl rubber)

- Funnel tools to prevent splashing during pouring

- Safety goggles or face shields should be worn during dispensing

These personal protective accessories should be part of any liquid-handling protocol involving cubitainers, especially in laboratories, manufacturing plants, or cleaning operations.

Optional Add-ons That Improve Convenience

While some accessories are essential, others provide added convenience that can streamline operations or enhance user comfort.

Handles or Carry Straps

Larger cubitainers (10L and above) can be difficult to carry when full. Reinforced handles or attachable straps:

- Improve grip and reduce physical strain

- Make manual transportation safer and more efficient

- They are particularly useful in mobile or field environments

Handles made from nylon webbing or ergonomic plastic are reusable and often adjustable to fit various cubitainer sizes.

Measuring Accessories

In precision environments, such as laboratories or food manufacturing, measurement accuracy is crucial. Accessories like:

- Graduated caps or volume indicators

- Inline flow meters for dispensing stations

- Integrated fill lines or color-coded markings

These tools help ensure accurate pouring and prevent overfilling or waste.

Heat-Sealed Liners or Replaceable Inner Bags

Some cubitainers are designed with inner bags that can be removed and replaced, extending the life of the rigid outer shell. Heat-sealed liners:

- Offer added protection against contamination

- Simplify cleanup after use

- Are suitable for pharmaceutical or sterile environments

This modular system supports circular packaging practices and reduces long-term costs.

Choosing the Right Accessories for Your Application

Not every cubitainer setup needs the same accessories. Your unique use case will determine which ones are best for ensuring efficiency, safety, and compliance.

Type of Liquid Stored

The liquid’s properties dictate the accessories needed:

- Flammable liquids require vented caps and anti-static trays.

- Corrosive substances need chemical-resistant taps and closures.

- Food-grade liquids call for FDA-approved, tamper-evident components.

- Viscous liquids benefit from high-flow taps or heated dispensing tools.

Selecting materials compatible with the stored substance prevents leaks, contamination, and degradation.

Regulatory Requirements

Different industries have varying compliance needs:

- Food and beverages must meet FDA/NSF standards.

- Chemicals and pharma may require OSHA– or REACH-compliant labeling and safety equipment.

- Environmental safety rules might call for secondary containment solutions.

- Meeting these standards reduces legal risk and enhances workplace safety.

Supplier Reliability and Compatibility

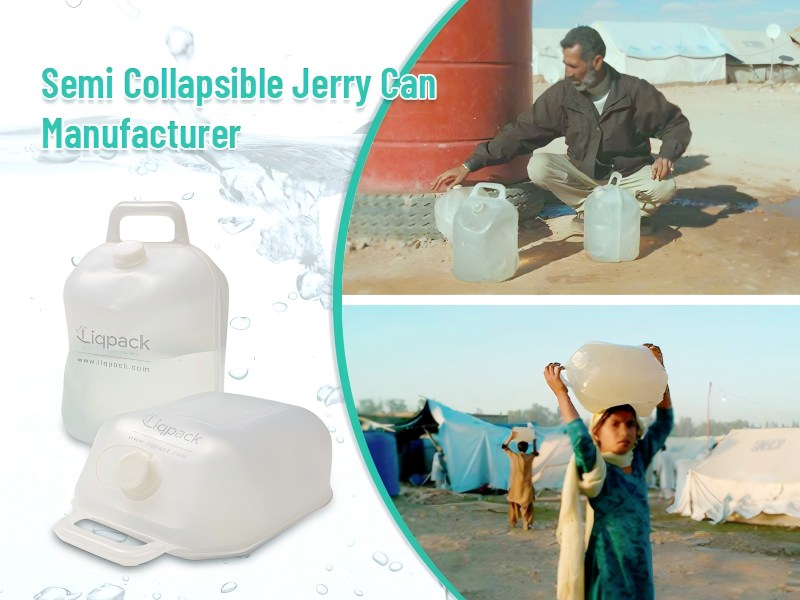

Choose accessories from trusted suppliers, Liqpack can provide:

- Match your cubitainer size and thread type

- Provide tested and durable materials

- Provide relevant documentation and replacement parts

Cubitainers are incredibly versatile, but their performance and safety improve dramatically when paired with the right accessories. From dispensing taps and secure closures to spill trays and labeling systems, these add-ons can transform a basic container into a reliable tool for liquid handling.

- Liqpack