You want packaging that supports sustainability, conserves space, and safeguards your liquid products. Cubitainers deliver these benefits with a lightweight, durable build that uses up to 80% less plastic than many alternatives. Their stackable design and handle options make storage and handling simple. You can recycle them fully, and their cap choices let you ship even hazardous liquids safely. When you look at a Cubitainer comparison with rigid bottles, drums, pouches, or bag-in-box, you see a solution that meets high standards for both performance and environmental responsibility.

Important Takeaways

- Cubitainers are a more environmentally friendly option because they use up to 80% less plastic than conventional packaging.

- Because of their foldable shape, they take up less room when being stored and transported, which lowers shipping expenses and their environmental impact.

- Cubitainers provide robust durability and leak resistance, guaranteeing spill-free, safe liquid transportation.

- The monomaterial construction of Cubitainers simplifies recycling, supporting a cleaner recycling stream.

- Cubitainers are adaptable and appropriate for a range of uses, including industrial, medicinal, and food applications.

Cubitainer Comparison: Cost

Purchase Cost

When you compare the initial purchase cost of Cubitainers to other liquid packaging options, you notice some important differences. Rigid bottles and cans often cost more to produce because they use more plastic or metal. Bag-in-box systems and pouches can seem cheaper at first, but they may require extra components or special filling equipment. Cubitainers use a monomaterial design, which helps keep manufacturing costs low. Additionally advantageous to you is their patented structure, which lowers the quantity of raw materials required. In a Cubitainer comparison with bottles, cans, and bag-in-box, you often find that Cubitainers offer a competitive price, especially when you consider the total cost of ownership.

Shipping & Storage

Shipping and storage costs can add up quickly, especially if you use bulky or heavy packaging. Cubitainers help you save money in these areas because of their flexible and collapsible design. When empty, you can flatten them, which means you need less space in your warehouse or during transport.

- Cubitainers occupy only 1/7 the space of a traditional blow-molded container.

- You can fit more units per pallet, which reduces shipping trips and lowers fuel costs.

- Their lightweight build also means you pay less for freight.

This space-saving advantage stands out in any Cubitainer comparison with rigid bottles or drums. You get more efficient logistics and lower overhead.

Long-Term Value

You want packaging that delivers value over time, not just at the point of purchase. Cubitainers offer several long-term benefits. Their high product ejection rate means you waste less liquid, so you get more out of every container. The monomaterial construction makes recycling easier, which can reduce disposal costs. If you automate your filling process, Cubitainers work well with many systems, helping you save on labor and increase productivity. These savings mount up over the course of months or years. In a Cubitainer comparison with other packaging types, you see that the reduced waste, lower shipping costs, and easier recycling all contribute to a better return on investment.

Durability

Leak Resistance

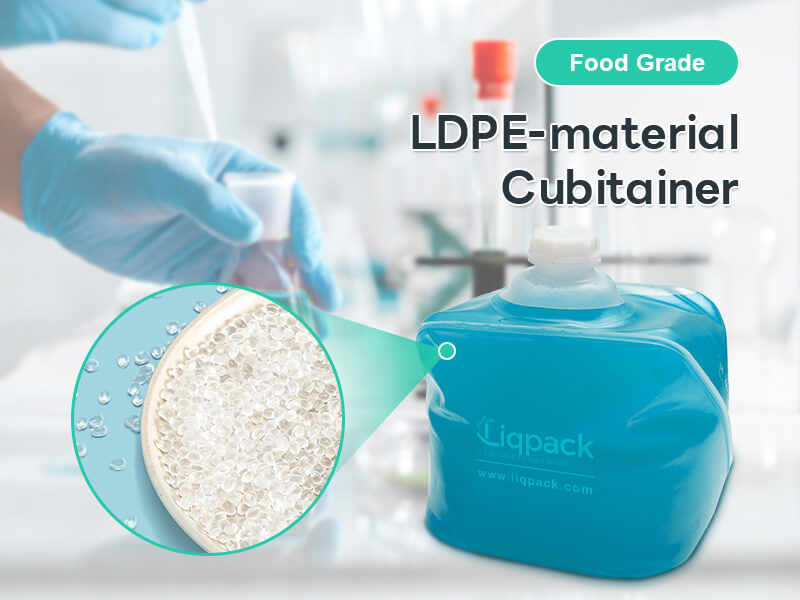

You want packaging that keeps your liquids secure. Cubitainers blend low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE) in a semi-rigid form. You get strength and flexibility from this mix. The non-glug design allows a steady flow, which helps prevent spills when you pour. You also get extra protection from the corrugated fiberboard overpack. This layer adds integrity and shields the container from punctures. When you compare Cubitainers to rigid bottles or drums, you notice fewer leaks and less risk of accidental spills.

- The semi-rigid build resists punctures better than thin pouches.

- The fiberboard overpack protects against sharp impacts.

- The non-glug spout reduces sudden splashes and spill risks.

You can trust Cubitainers to keep your products safe, even if you handle them often or ship them long distances.

Transport Efficiency

Packaging must be able to withstand the difficulties of storage and transportation. Cubitainers perform well in transit because their flexible walls absorb shocks. Rigid bottles and drums may crack or dent if dropped, but Cubitainers bounce back from impacts. The fiberboard overpack adds another layer of defense, so you see fewer damaged units on arrival. Pouches and bag-in-box systems can tear or leak under pressure, but Cubitainers maintain their shape and integrity.

- Tip: If you ship liquids that require extra care, Cubitainers offer a reliable solution. Their design protects your products from leaks and damage during transport.

In a Cubitainer comparison with other packaging types, you find that Cubitainers deliver strong durability for both leak resistance and transport performance. Knowing that your things arrive securely gives you peace of mind.

Environmental Impact

Recyclability

You want packaging that supports recycling efforts. Cubitainers use a monomaterial design, which means each container is made from a single type of plastic. This approach offers several advantages:

- You can recycle Cubitainers more easily because recycling facilities do not need to separate different materials.

- Monomaterial packaging helps reduce sorting errors and speeds up the recycling process.

- Cubitainers encourage greater recycling rates than multi-material packaging, which frequently ends up in landfills because of its intricate layers.

- New innovations, such as advanced barrier coatings, allow monomaterial packaging to meet strict performance standards while staying recycle-ready.

When you choose Cubitainers, you help create a cleaner recycling stream and support the future of sustainable packaging.

Materials & Waste

You can make a big difference in waste reduction by switching to Cubitainers. These containers use up to 80% less plastic than traditional rigid bottles or drums. This reduction means you generate less plastic waste with every shipment. The space-saving design lets you transport more units at once, which lowers fuel use and cuts emissions. When you look at a Cubitainer comparison with other packaging types, you see a clear advantage in carbon footprint. Studies show that switching from rigid containers to Cubitainers can reduce CO₂ emissions by up to 85%. By selecting packaging that produces less trash and utilizes fewer resources, you may contribute to environmental protection.

Convenience

Filling & Dispensing

You want packaging that makes filling and dispensing simple. Cubitainers offer a lightweight design that you can handle easily. You can fill them quickly because their wide opening fits most filling equipment. The flexible walls allow you to squeeze out almost every drop, so you waste less product. Liquids can be dispensed without the use of complex equipment or specialized tools. The built-in handle gives you a firm grip, which helps you pour with control. You can choose from different cap options to match your needs, whether you want a tamper-evident seal or a spout for precise pouring.

- Tip: If you need to fill or dispense liquids in a busy environment, Cubitainers help you save time and reduce mess.

You can clean up faster and move on to your next task. In a Cubitainer comparison with rigid bottles or drums, you see that Cubitainers make handling liquids much easier.

Space Efficiency

You want to use your storage space wisely. Cubitainers fold flat when empty, so you can stack them and free up room in your warehouse. You can fit more units on a pallet, which means you ship more product in fewer trips. This efficient use of space lowers your transportation costs and helps you manage inventory better.

Here is a quick look at how Cubitainers compare to other packaging types:

| Container Type | Space Efficiency |

| Plastic Cubitainers | Highly efficient due to foldability and compact storage |

| Rigid Bottles | Less efficient, takes up more space when stored |

| Drums | Least efficient, cannot be compacted when not in use |

You benefit from several user-reported advantages:

- Effective cube utilization helps you avoid off-site storage.

- You maintain optimal inventory levels, which keep your operation running smoothly.

- Lower fuel prices and emissions result from fewer transportation trips.

- Efficient space usage saves money in logistics.

- You improve customer service by keeping products available.

- Sustainable practices become easier with reduced transportation needs.

You get more value from your storage and shipping operations when you choose Cubitainers.

Application Suitability

Food & Beverage

You need packaging that keeps food and drinks safe and fresh. Cubitainers offer a hygienic solution for liquid foods and beverages. The inner bag and protective outer box create a sealed environment. This design lowers the possibility of infection and contamination. You can trust Cubitainers because they use high-grade, food-safe plastic materials. These materials meet strict industry standards for hygiene and product safety.

- You get a non-contaminating package that protects your product from external risks.

- The sealed system keeps liquids pure and minimizes exposure to air or bacteria.

- Food-safe plastics ensure compliance with regulations in the food sector.

You can use Cubitainers for cooking wines, mirin, millet wine, liquid sugar, and sauces. These containers work well for spirit vinegar and other specialty liquids. Restaurants, food processing facilities, and catering businesses all employ cubitainers. The flexible design makes filling and dispensing easy, even in busy kitchens.

Note: Cubitainers help you maintain high hygiene standards and simplify handling for food and beverage products.

Industrial & Chemical

You need packaging that stands up to tough industrial and chemical environments. Cubitainers carry liquid and semi-liquid products with ease. You see them used for paints, stains, coatings, and cleaning agents. The durable build resists punctures and leaks, which is important for chemicals that require safe transport.

- You can package cooking wines and sauces for industrial kitchens.

- You can use Cubitainers for liquid sugar in food manufacturing.

- You can rely on them for industrial chemicals and specialty liquids.

| Product Type | Packaged in Cubitainers | Other Solutions |

| Beverage | Yes | Yes |

| Industrial Chemicals | Yes | Yes |

| Cooking Wines | Yes | No |

| Liquid Sauces | Yes | No |

| Spirit Vinegar | Yes | No |

You benefit from lower shipping costs compared to standard plastic pails. Cubitainers are more durable than bag-in-box alternatives. Their lightweight and space-efficient design makes them ideal for remote areas or locations with limited storage.

- You save money on logistics.

- You reduce product loss due to leaks or damage.

- You improve safety for workers handling chemicals.

You see a clear advantage in Cubitainer compared with other packaging solutions for industrial and chemical uses.

Medical & Pharma

You need packaging that meets strict medical and pharmaceutical standards. Cubitainers serve the pharmaceutical industry by providing secure and sterile liquid packaging. The collapsible design combines the benefits of rigid bottles with sustainability. You can rely on Cubitainers to protect sensitive products and maintain sterility.

- Medical packaging must protect products from contamination.

- You need compliance with unique specifications and sterilization requirements.

- Adherence to high medical standards ensures safety for patients and healthcare workers.

Cubitainers use regulatory-compliant materials that guarantee safety and effectiveness. They are utilized for medical liquids such as saline solutions and diagnostic reagents. The sealed system keeps products sterile during transport and storage.

- Tip: Cubitainers help you meet regulatory demands and maintain product integrity in medical and pharmaceutical applications.

You can trust Cubitainers for hygiene-sensitive uses in hospitals, laboratories, and clinics. Their design supports both safety and sustainability, making them a smart choice for medical packaging.

Cubitainer Comparison Table

When you want to make an informed decision about liquid packaging, you need to look at real-world data. A comparison table helps you see how Cubitainers perform against other options in the market. You can use these metrics to understand cost, sales, and market trends. You can see exactly where Cubitainers stand using this method.

Here is a table that summarizes the most important metrics used by industry experts:

| Metric | What It Tells You |

| Sales Volume | Number of Cubitainers sold by manufacturers and regions |

| Price | Selling price based on size, type, and market |

| Cost | Manufacturing cost for each Cubitainer |

| Gross Revenue | Total money earned from Cubitainer sales |

| Gross Margin | Profit made after subtracting costs from revenue |

| Global Market Share | Percentage of the market Cubitainers hold worldwide |

| Revenue by Regions | How much revenue comes from different parts of the world |

| Revenue by Manufacturers | Comparison of revenue among the top Cubitainer producers |

| Revenue by Types | Revenue from different Cubitainer sizes and designs |

| Revenue by End Users | Revenue from industries like food, chemicals, and pharmaceuticals |

You can use this table to compare Cubitainers with rigid bottles, drums, pouches, and bag-in-box solutions. For example, if you want to know which packaging type sells the most units, look at the sales volume. If you care about profit, check the gross margin. When you want to see which regions prefer Cubitainers, review the revenue by regions.

- Tip: Use these metrics to match your business goals. If you want to lower costs, focus on manufacturing cost and gross margin. If you want to expand, look at global market share and revenue by regions.

By knowing these parameters, you can choose the most suitable packaging solution. By fully grasping the market, you can make wiser product selections.

When you review a Cubitainer comparison with other packaging, you see clear strengths in cost, durability, and sustainability. You get easy handling and strong leak protection. Some applications may need rigid containers, but Cubitainers work best for those who want space savings and eco-friendly options. Think about your product, shipping needs, and recycling goals. Choose the packaging that matches your priorities.

- Liqpack