Liqpack Products

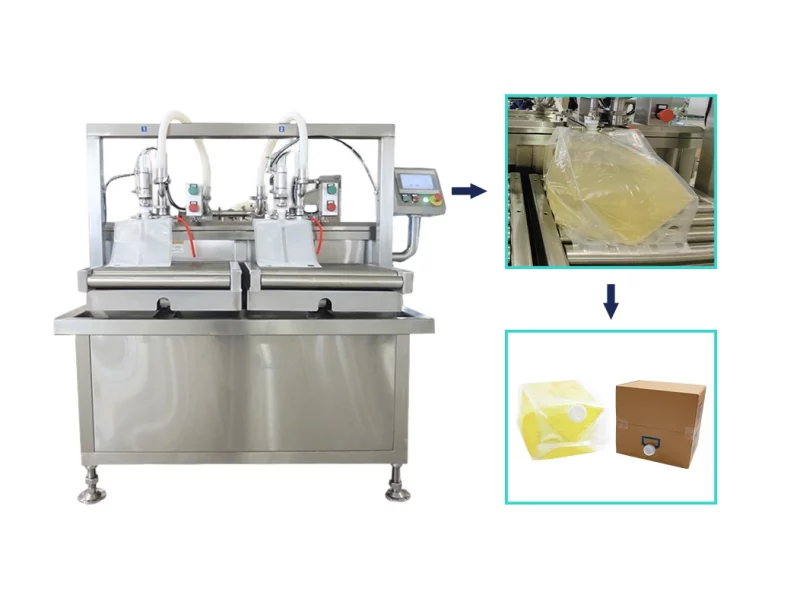

Bag-In-Box Filling Machine

- Our double-head semi-automatic bag in box filling machines for cheertainer is engineered for precise filling of liquid products into flexible cheertainer soft bags.

- The bag in box filler machine integrates bag positioning, cap opening, filling, and capping in a fully automated sequence.

- Designed with stainless steel construction and a high-accuracy weighing system, it ensures stable performance under continuous operation.

Construction Materials of Bag-in-Box Filling Equipment

|

|

Performance Parameters |

|

| Filling Heads | 2 |

| Output | ≤ 100 bags/hour |

| Filling Accuracy | Weight-sensor controlled, optimised for low-viscosity and medium-viscosity liquids |

| Power Requirement | AC220V, 50Hz |

| Rated Power | 1 kW |

| Air Supply | 0.5–0.6 MPa clean compressed air |

| Operating Temperature | 5°C–35°C |

| Relative Humidity | ≤ 85% |

| Noise Level | ≤ 75 dB |

Applications of Semi-Automatic Bag-in-Box Filling Machines

|

|

|

| Food and beverage | Dairy and condiments | Detergents and cleaning liquids |

|

|

|

| Chemical solutions | Water and household liquids | Industrial and agricultural liquids |

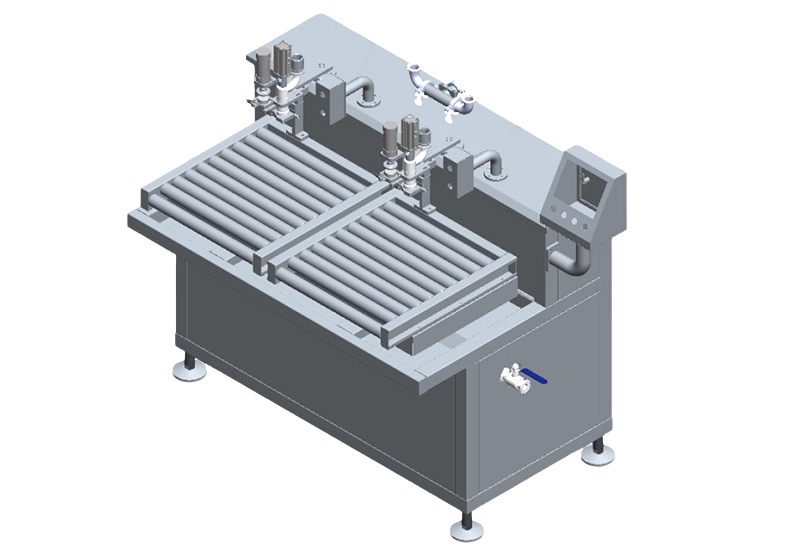

Mechanical Properties of Automatic Bag-in-box Filling Machine

|

|

|

|

Working Process of Bag-in-box Filling Machines

|

Human–Machine Interface (HMI)

|

Safety Systems of Custom-designed Bag-in-box Filling Machines

|

|

The bag-in-box filling machine’s Maintenance Requirements

|

Review Your Product’s Features

Before Choosing a Semi-Automatic Bag-In-Box Filler

- Low-viscosity liquids (water-based beverages, cleaning agents)

- Medium-viscosity liquids (oils, detergents, sauces)

- Sensitive liquids that require hygienic contact surfaces

Suitable filling equipment for the Cheertainer bag-in-box should use 316L stainless steel for all product-contact surfaces to maintain hygiene and prevent corrosion.

|

|

|

| Low-viscosity liquids | Medium-viscosity liquids | High-viscosity liquids |

OEM Services During Our Gag-in-box Machine Manufacturing

|

|

|

ODM Services

|

|

|

Why Work With Us?

|

|

|

|

| Experienced engineering team | Food-grade manufacturing capability | Reliable quality control systems | Long-term after-sales support |

Our Experience with Bag-in-Box Filling System

When choosing a bag-in-box filling equipment for Cheertainer, select a manufacturer as Liqpack with experience in:

- Bag-in-box systems

- Liquid processing equipment

- OEM/ODM customisation capability

- This ensures your machine fits your exact production needs.

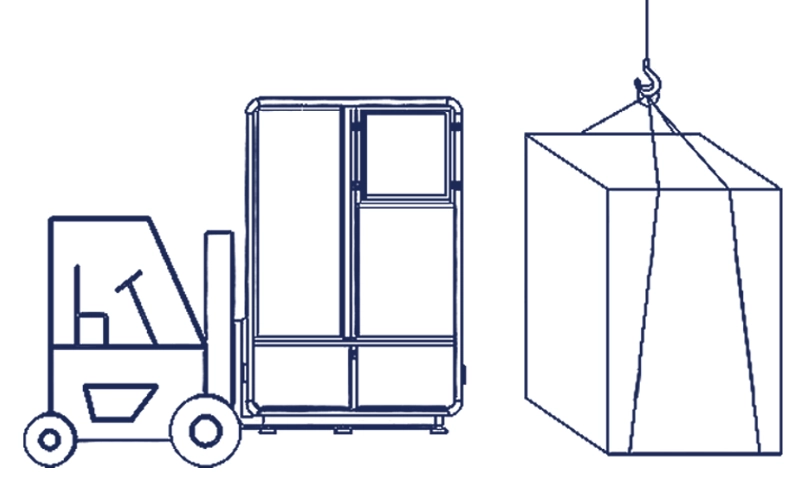

Packing and Loading of the filling machines.

|

|

|