Semi-collapsible jerry cans are essential for storing and transporting liquids in remote, emergency, and industrial settings. Their space-saving design balances durability and flexibility, but improper use can cause leaks or damage. This article highlights common mistakes and offers tips to ensure safe, long-lasting use.

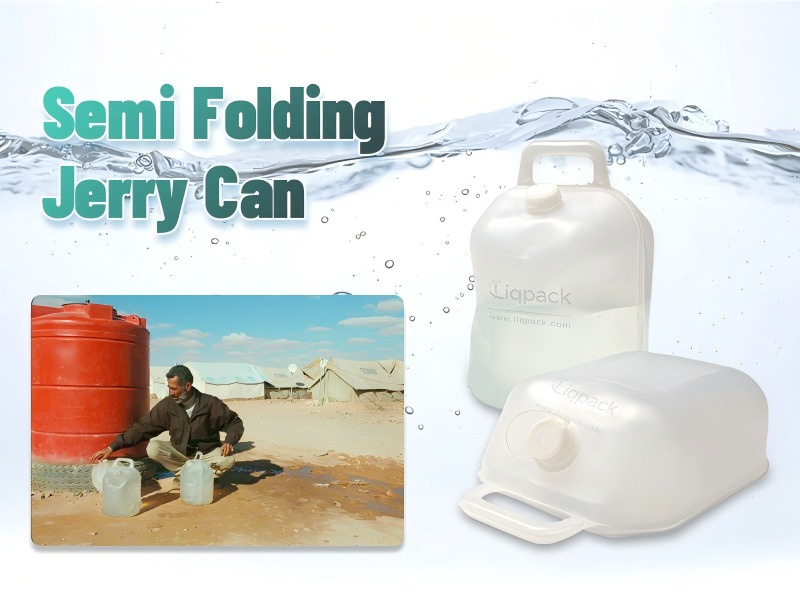

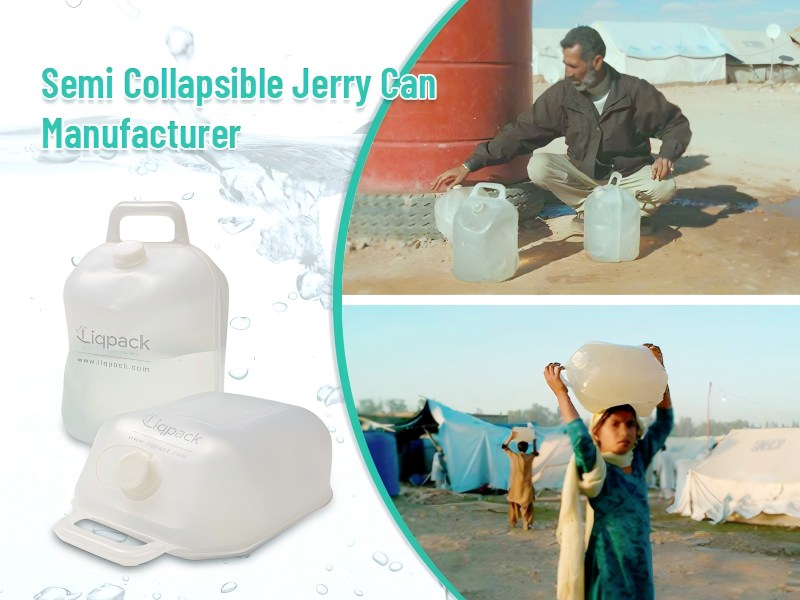

What Are Semi-Collapsible Jerry Cans?

Semi-collapsible jerry cans are hybrid containers featuring a rigid top and base with flexible, collapsible walls. They combine the strength of rigid containers with the compactness of collapsible ones, making them ideal for field deployment, medical supply chains, camping, military use, and humanitarian operations.

These containers often comply with international standards such as UN transport regulations and WHO water safety guidelines, making them a preferred choice for NGOs, medical missions, and logistics companies.

Mistake #1: Overfilling the Jerry Can

One of the most frequent errors is overfilling the container beyond its safe capacity. This not only risks spillage but also increases internal pressure, which can deform the flexible sides and damage the structural seams.

How to Avoid It:

- Follow the fill line indicators marked on the can.

- Allow for expansion space, especially in hot environments.

- Use a funnel with a volume gauge for precision during filling.

Mistake #2: Using the Wrong Liquids

Semi-collapsible jerry cans are typically designed for water or compatible non-corrosive liquids. Filling them with chemicals, oils, fuels, or solvents may result in chemical reactions that weaken the plastic, cause leakage, or contaminate the contents.

How to Avoid It:

- Always check the material compatibility list provided by the manufacturer.

- Never store flammable or acidic substances unless explicitly approved.

- Label each Jerry can to avoid cross-contamination.

Mistake #3: Improper Cleaning and Maintenance

Failing to regularly clean your jerry can can lead to bacterial growth, residue buildup, or foul odors—especially if it’s used to store potable water. Mold and sediment can damage the interior lining over time.

How to Avoid It:

- Rinse thoroughly with mild detergent and clean water after each use.

- Periodically sanitize using a diluted bleach solution (1 tsp per liter of water).

- Allow to air dry fully before collapsing or storing.

Mistake #4: Exposure to Excessive Sunlight or Heat

Placing a semi-collapsible jerry can under direct sunlight or next to heat sources can degrade its material. This can reduce flexibility, weaken joints, and alter the contents, especially in the case of water meant for drinking.

How to Avoid It:

Store Jerry cans in a shaded, cool location whenever possible.

Use UV-resistant covers or select models made with UV-protective polymers.

Avoid placing containers near engines, stoves, or open flames.

Mistake #5: Mishandling During Transport

Rough handling during loading or transportation may result in punctures, tears, or deformation of the soft side walls. The structural integrity of the can may be jeopardized if they are stacked incorrectly or are dropped when full.

How to Avoid It:

Use padded crates or cushioned compartments during transport.

Secure containers with straps or netting to prevent sliding.

Don’t place bulky objects on top of the jerry cans.

Mistake #6: Ignoring Regulatory Standards

Using non-certified jerry cans or continuing to use containers past their shelf life can lead to regulatory non-compliance, especially in medical or relief contexts. WHO and UN standards exist for a reason—using outdated or non-compliant jerry cans can compromise entire operations.

How to Avoid It:

Only purchase from certified suppliers who meet UN/WHO standards.

Check the manufacturing and expiry dates printed on the can.

Train your team to recognize non-compliant or damaged containers.

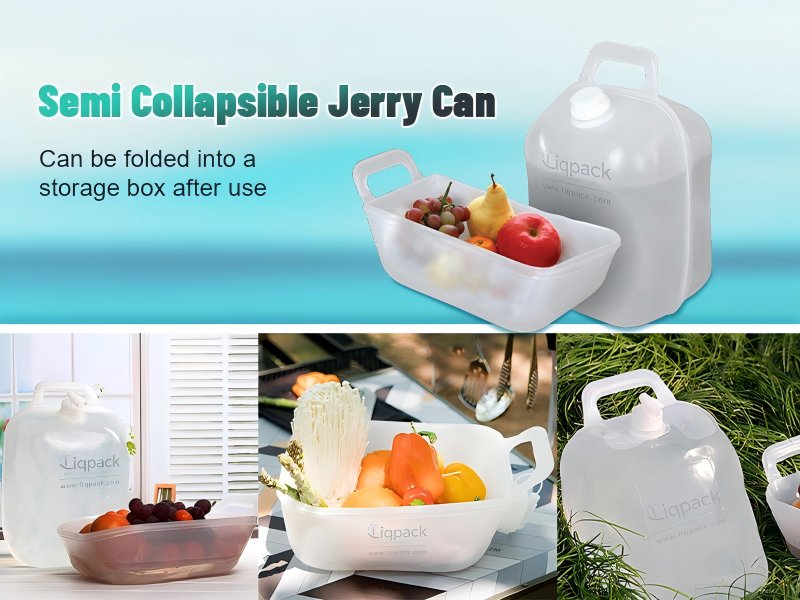

Mistake #7: Incorrect Folding or Collapse Method

Improper folding of the collapsible sections can lead to crease damage, internal stress points, and even cracks. If you force it into a compact shape too quickly, it could affect future usability.

How to Avoid It:

- Follow the manufacturer’s folding instructions—some require a roll, others a flat fold.

- Collapse only after full drying to avoid trapped moisture.

- Use light pressure rather than brute force when folding or stacking.

Mistake #8: Reusing Single-Use Jerry Cans

Some jerry cans are designed for single-use, particularly those used for medical aid or water drops in crisis zones. Reusing them without knowing their limitations can result in dangerous degradation or contamination.

How to Avoid It:

- Identify reusable vs. disposable models from the product code.

- Inspect for signs of plastic fatigue, discoloration, or seam damage.

- Even if they appear to be functional, replace jerry cans as soon as they begin to show wear.

Mistake #9: Neglecting Leak Testing Before Use

Skipping a pre-use inspection can mean discovering a leak too late—in the field or mid-transport. A slow seam leak or pinhole can waste precious water or contaminate cargo.

How to Avoid It:

- Conduct a simple fill-and-tilt test before each use.

- Check for air bubbles by lightly squeezing filled cans.

- Keep a log of inspection dates and issues for team accountability.

Best Practices for Safe and Efficient Use

To ensure your semi-collapsible jerry cans last long and perform reliably, follow these best practices:

| Do’s | Don’ts |

| Use only for approved liquids | Store gasoline or strong acids |

| Clean and dry thoroughly after each use | Fold while wet |

| Store in cool, shaded areas | Leave in direct sun for hours |

| Conduct regular inspections | Ignore small leaks or odor |

| Follow the folding instructions | Force or twist sides during collapse |

Consider creating a checklist for field teams that includes inspection, filling, labeling, cleaning, and transport protocols. Regular training, visual guides, and supplier support can reduce costly handling mistakes.

Semi-foldable drums offer efficient and flexible liquid storage, but only if used correctly. Avoiding overfilling, chemical abuse, and sun exposure helps ensure safety and longevity. Selecting certified models and training employees improves reliability and compliance.

- Liqpack