As global industries seek more efficient, safe, and sustainable liquid packaging solutions, Cubitainers—collapsible, semi-rigid containers made from high-quality polyethylene—have emerged as a preferred choice. Known for their space-saving design, chemical resistance, and easy dispensing features, Cubitainers are revolutionizing how companies store and transport liquids. These containers are particularly advantageous where cleanliness, lightweight handling, and product purity are priorities.

This article explores ten industries that significantly benefit from Cubitainers, highlighting the reasons behind their adoption and the unique advantages they bring to each sector.

Pharmaceutical and Healthcare Industry

In the pharmaceutical sector, cleanliness, sterility, and precise dispensing are non-negotiable. Cubitainers meet stringent regulatory requirements for drug manufacturing, diagnostic reagents, and medical-grade fluids. They are used for:

- Storing sterile solutions like saline and alcohol

- Dispensing diagnostic reagents in laboratories

- Handling high-purity water and buffer solutions

Their inert material and tamper-evident design reduce contamination risks. Also, Cubitainers can be gamma sterilized or used with sterile liners, ensuring safety during sensitive medical applications.

Food and Beverage Industry

Cubitainers are widely used to package syrups, oils, sauces, juice concentrates, and even drinking water. The food-grade polyethylene used in Cubitainers is approved by the FDA and other global food safety authorities, ensuring compatibility with edible contents.

Key benefits include:

- Protection against oxygen and moisture ingress

- Easy dispensing without spillage or air contact

- Collapsibility, which reduces space during shipping and storage

For mobile food vendors and institutional kitchens, Cubitainers are convenient, hygienic, and eco-friendly alternatives to rigid bottles or drums.

Agricultural and Agrochemical Industry

In agriculture, chemicals like pesticides, fertilizers, and plant growth regulators require secure and compatible packaging. Cubitainers are resistant to many aggressive chemicals and minimize leakage during transport.

Agricultural suppliers use them to:

- Store and dispense liquid fertilizers and micronutrients

- Transport pesticides safely

- Mix agrochemicals with water at the point of use

Since Cubitainers are lightweight and collapsible, farmers find them easier to handle in the field compared to bulky drums or jerrycans.

Cosmetic and Personal Care Industry

The cosmetics industry increasingly relies on Cubitainers for storing and transporting bulk lotions, creams, shampoos, and gels. The smooth interior surface prevents product residue, which is crucial for high-viscosity personal care products.

Advantages include:

- Clean dispensing without air contamination

- No leaching of plasticizers or chemicals

- Reduced packaging waste in the manufacturing environment

These features are especially valued in GMP-compliant cosmetic production facilities where hygiene and traceability matter.

Chemical Manufacturing

Cubitainers are ideally suited for handling acids, alkalis, surfactants, solvents, and other industrial chemicals. Compatibility with a variety of harsh substances is guaranteed by their chemical resistance.

In chemical plants, Cubitainers are used to:

- Store intermediate liquids before final formulation

- Package small-batch specialty chemicals

- Safely ship hazardous liquids with UN-certified options

Their transparent structure allows visual inspection of contents, which aids in quality control and inventory management.

Cleaning and Sanitation Products Industry

The demand for surface disinfectants, sanitizers, detergents, and industrial cleaning solutions has surged, especially post-pandemic. Cubitainers offer a hygienic and efficient way to package and distribute these liquids.

Key reasons for adoption include:

- Easy integration with bulk refill stations

- Leak-proof dispensing systems

- Reduced plastic usage compared to rigid containers

For institutional cleaners and commercial laundry services, Cubitainers reduce packaging waste while simplifying storage and dispensing operations.

Laboratories and Research Facilities

Laboratories often require high-purity solvents, reagents, and buffer solutions. Cubitainers, with their cleanroom-ready designs, offer contamination-free storage and transfer.

Used in:

- Biotech and pharmaceutical R&D labs

- Analytical chemistry applications

- Clinical testing facilities

Labs appreciate Cubitainers for their precise, gravity-based dispensing, minimal waste, and ability to maintain chemical integrity during storage.

Automotive and Industrial Lubricants

Cubitainers are gaining ground in the automotive sector, especially for packaging oils, lubricants, antifreeze, brake fluids, and additives. They are safe for greasy or viscous materials because of their robustness and pressure resistance.

Benefits include:

- Minimized spillage during dispensing

- Customizable spouts and nozzles for workshop use

- Reduced container weight and disposal costs

Auto service centers and industrial machinery operators find Cubitainers practical for storage, dispensing, and handling in limited spaces.

Paints, Coatings, and Inks Industry

Many liquid coatings, inks, and additives require air-tight, contamination-free packaging. Cubitainers help prevent oxidation and drying by collapsing as contents are dispensed, limiting air exposure.

Ideal for:

- Water-based and solvent-based paints

- Industrial printing inks

- Additive concentrates and dyes

They’re also used by DIY paint suppliers for refill programs, thanks to their ease of use and recyclability.

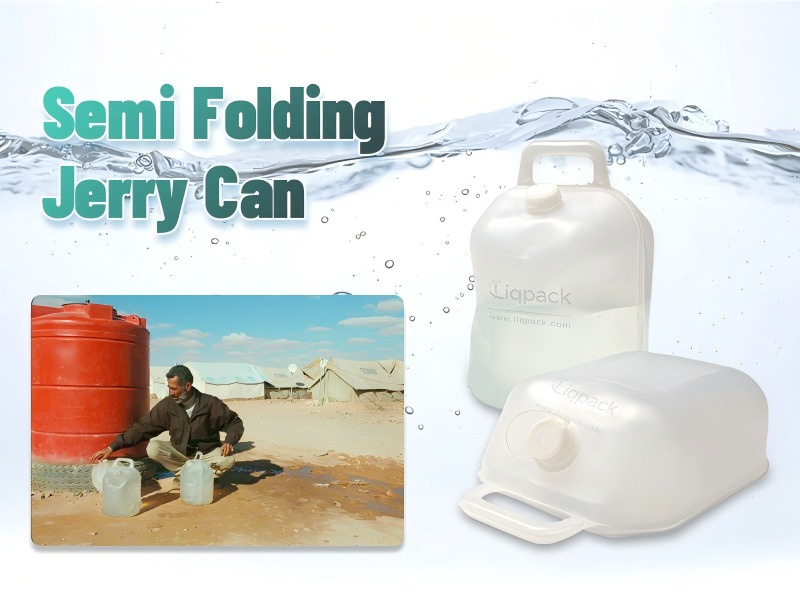

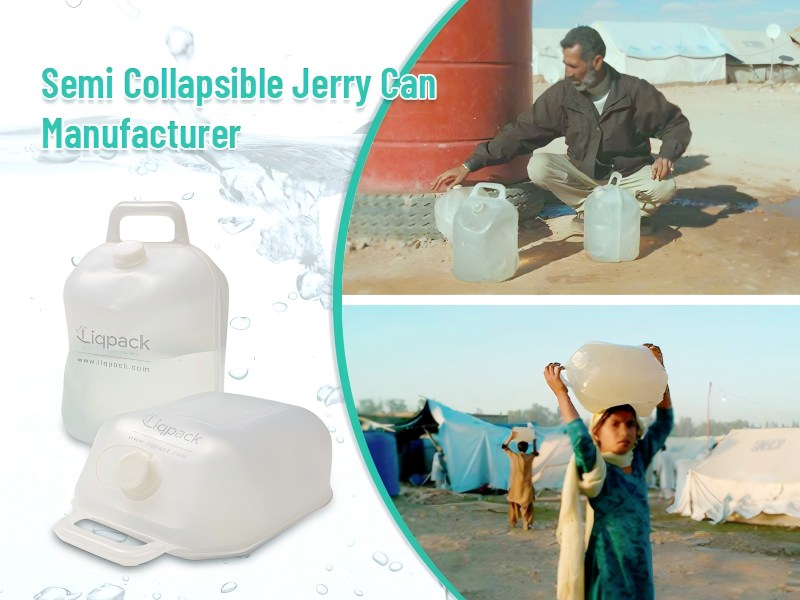

Emergency and Humanitarian Relief Operations

In disaster response and remote field operations, reliable water and liquid transport are essential. Cubitainers offer a safe and collapsible method to supply:

- Clean drinking water

- Disinfectants and soaps

- Nutritional liquids

Their stackability and light weight make them easy to deploy via airlift or overland transport. Relief organizations favor Cubitainers for their compact storage before use and safe reuse or disposal after deployment.

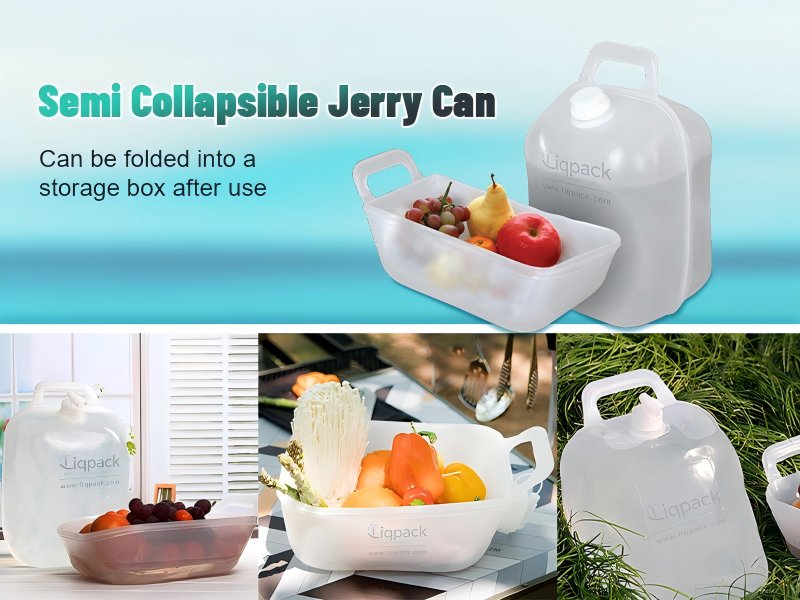

Environmental and Economic Benefits Across Industries

Beyond individual sector advantages, Cubitainers offer cross-industry benefits:

- Reduced carbon footprint: Lightweight and collapsible nature lowers shipping emissions and fuel costs.

- Lower storage costs: Folded containers save warehouse space when empty.

- Waste minimization: Precision dispensing systems reduce leftover product and spillage.

- Recyclability: Made from recyclable polyethylene, Cubitainers align with circular economy principles.

These benefits result in significant operational savings and sustainability improvements in high-volume businesses.

Design Features That Make Cubitainers Ideal

Cubitainers combine the strength of rigid containers with the flexibility of soft packaging. Key features include:

- Integrated spouts and closures: Offer controlled dispensing

- Collapsible walls: Prevent air contact and reduce product oxidation

- Stackable cardboard overpacks: Add rigidity and easy labeling for logistics

- Customization: Available in a range of sizes (1L to 20L+), shapes, and materials for different industries

We can also offer UN/DOT-compliant Cubitainers for shipping hazardous liquids.

Liqpack’s cubitainers have revolutionized liquid packaging in a variety of sectors, including food, chemicals, pharmaceuticals, and disaster relief. Benefits in hygiene, space saving and cost-effectiveness make them indispensable for performance-focused and sustainable businesses.

- Liqpack